LOG 100-500 kg

Autoclave system for infectious medical waste

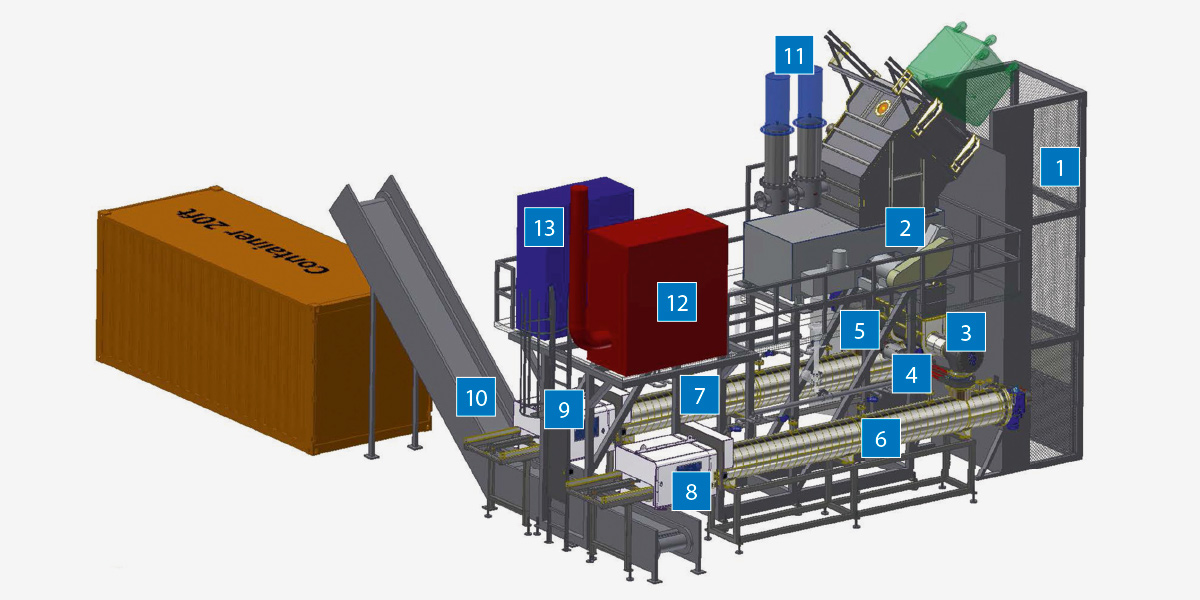

Plant components

1lifting tipping station up to 1100 ltr.-containers

2single shaft shredder WS-30 – 45 kW – 2000 kg/h

3distributing screw Ø350 mm and bunker

4knife gate valve VNC DN 350 autoclave 1

5knife gate valve VNC DN 350 autoclave 2

6autoclave 1 with screw Ø550 mm and double jacket

7autoclave 2 with screw Ø550 mm and double jacket

8autoclave cover 1 DN 600

9autoclave cover 2 DN 600

10conveyor belt BB 500 mm

11prefilter f9 and sterile filter H14

12steam generator

13water treatement for steam generator

To provide on site

− electric power 400 V, 250 A

− gas for steam generator

− water

Process procedure

- filling by containers with lifting tipping station1

- suction during opening the hopper through prefilter h9 and sterile filter H1411

- crushing with single shaft shredder2

- filling the distribution screw und bunker3

- filling of the autoclaves by screws inside6 7

- reversing movement of the autoclave screws throughout the process

- heating with steam up to 138 ° C / 3.5 bar abs.

- holding time in saturated steam at 138 ° C / 3.5 bar abs. 15 min.

- drain pressure and dry

- emptying the waste via process screw and conveyor belt10

Sterilization of the hopper, shredder room, distribution screw, bunker and filters

1. steam through-flow at 104 °C / 1.15 bar abs.

2. holding time in saturated steam at 104 °C / 1.15 bar abs.

Behavior of the system in case of failure of media and components

In the event of a failure of electricity, steam and compressed air as well as in the event of a failure of the control, the machine goes into a safe operating state; valves and covers remain closed until the machine is ready for operation again and the processes can be completed.